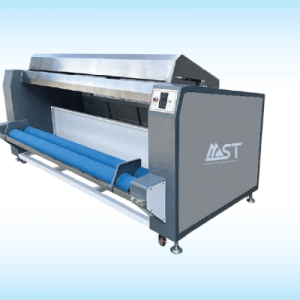

Product feature:

The machine features one independent pre-heating zone, two steam sponging zones, four heating zones, and one cooling zone, all connect by the conveyor belt.

● Pre-heating zone heating’s the mesh belt, preventing water droplets on it during cold winter months due to low temperatures.

● Steam sponging shrinking and softens the fabric. The fully enclosed steam chamber maintains steam temperature, humidity, and pressure for more thorough sponging effect.

● Adjustable drying temperature and speed.

● Special conveyor belt design eliminates concerns about belt deviation.

● Measurement and fabric length counting available.

● Accepts roll – fed fabric and outputs relaxed fabric.

![]() Applicable fabric types

Applicable fabric types

Knit and woven, a variety of general fabric. Especially synthetic for pure cotton, silk, wool, linen, synthetic fiber and mixed fabric.