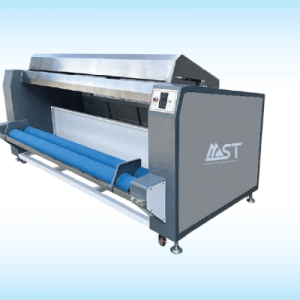

Product feature:

The machine is equipped with one set of steam humidification pre-shrinking area, two sets of drying area and one set of cooling area, and each area is connected by conveyor belt.

![]() Drying temperature adjustable & Speed adjustable

Drying temperature adjustable & Speed adjustable

![]() Special conveyor belt structure, no need to worry about conveyor belt deviation

Special conveyor belt structure, no need to worry about conveyor belt deviation

![]() Measurement, fabric length counting

Measurement, fabric length counting

![]() Available for Input Roll fabric and Output Relaxing fabric.

Available for Input Roll fabric and Output Relaxing fabric.

![]() Applicable fabric types: Knit and woven, a variety of general fabric.

Applicable fabric types: Knit and woven, a variety of general fabric.